Summary

Hunan Along New Energy Technologies Co., Ltdcan provide a entire solution from waste to energy, scope of equipment supply covers waste pre-treatment, anaerobic fermentation, biogas cleaning, Combined Heat&Power Unit(CHP), Bio-natural Gas making system, biogas flare/boiler and all auxiliary materials, in conjunction with services of process design, equipment selection, installation and operation & maintenance support.

ALONG BIOGAS is also professional in sewage treatment with non-production of biogas, with purpose of cleaning waste water for recycling of process water or being discharged environmental friendly.

General Process Description for each stage of a complete Biogas Project

1.Waste Material and Pre-treatment

Single or mixture of multiple substrates with high content of organic substance can be used for biogas production. Waste materials and by-products are accrued in conjunction with every single manufacturing operation, from-Animal husbandry

-Slaughterhouses

-The food-production industry and the food-processing industry

-Agriculture raw and residual waste, e.g. Strew,semi-rotten vegetable&fruit

-Supermarkets, e.g. spoiled food products

-Breweries (malt spent grains)

-Restaurants

-Juice production

-The ethanol industry (mash)

-The biofuel industry, e.g. glycerine

-Purification plants: Sewage sludge

-The animal feed industry

For feedstock in forms of solid or solid-liquid mixture, such as crop stalks, fruit and vegetable waste, food waste, etc., they should be shred to a fine dimension before fed into digester. Involving equipment such as shredders, crushers, beater, grinding system,dissolving devices etc. Kitchen garbage or community waste, due to its complex compositions, special manual or automatic sorting devices are needed.

Separation process occupies a large proportion in the stage of pre-treatment of waste materials, to remove large particles of inorganic suspended solids, debris and the like contained in the waste water. The equipment used are generally like screw-squeezed, spiral centrifugal, rotary mechanical grille, inclined sieving separator. Grease-water separator or horizontal spiral centrifuge to be used for grease separation if waste contains oil.

For waste materials with high consistence of fiber, long impurities and the like, cutting and grinding devices are required for further processing. For example poultry droppings, which contains soft feathers, it’s difficult for primary solid-liquid separation to remove it, a special cutting&grinding system is wanted to solve such problem.

The feedstock should be cleaned, in order to ensure that it is harmless(from the point of view of hygiene) and it’s free of pathogens, to avoid bad affection for microbiological process in digester.

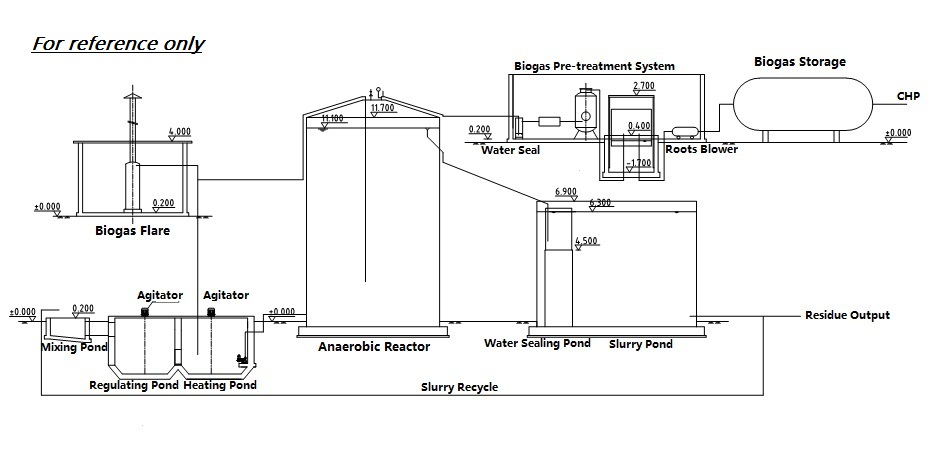

2.Anaerobic Fermentation

In the heated and air-tight digester, the biomass ferments in conjunction with the production of methane, mixed with other by-product gas, it’s so called biogas. The microbiological process in digester takes place in four stages, hydrolysis - acidification - acetic acid formation - methane formation.According to the characteristics of TS total solids, SS suspended solids, COD, BOD etc in the waste water, we will choose the best suitable anaerobic fermentation process among the following types:

- CSTR Reactor (Continuous Stirring Tank Reactor). The feedstock to be fed into digester through bottom entrance. Digester is equipped with mechanical agitators, enables waste materials to be in full contact with micro-organisms. The biogas slurry is automatically discharged and the residue is periodically pumped out of digester. Biogas generated is collected in the gas holder at the top of the reactor or flows into the free-standing gas holder on the ground. Proper TS(total solid) content varies in the range 6% to 12%, HRT(hydraulic retention time) varies from 20 to 30 days depending on the actual TS% and reactor temperature.

- USR Reactor (Up-flow Solid Reactor). USR reactor is a simple structure, suitable for sewage with high content of suspended solids. Waste is pumped into digester from bottom of reactor, and contact with activated sludge during up-flowing, so that the biomass to be quickly fermented. Unprocessed biomass solid particles and microorganisms remains inside reactor by natural sedimentation, and the bio-liquid overflows from the upper part of the digestor. Proper TS(total solid) content varies in the range 3% to 5%, HRT(hydraulic retention time) is about 10~15 days.

- UASB Reactor (Up-flow Anaerobic Sludge Blanket). The feedstock enters digester through the water distributor at the bottom of the reactor. Above the water-distributor there is a high concentration, highly active sludge blanket, where most of the organic matter is dissolved and fermented to methane and carbon dioxide. Due to the stirring of water flows and bubbles that full of biogas, there is a floating sludge layer above the sludge blanket. Gas,Liquid and sludge particle Solids are separated automatically through a special three-phases mechanical separator. Biogas flows into the gas storage chamber, sludge particles automatically fall to the sludge blanket, slurry gets out of reactor at clarification chamber. Proper TS(total solid) content is about 1%, HRT(hydraulic retention time) is about 5 days.

- EGSB Reactor (Expanded Granular Sludge Blanket). EGSB is the third generation of anaerobic reactors developed on the basis of UASB. Unlike UASB, EGSB has a dedicated sewage recovery device. The expanded Blanket of granular sludge improves contacting between organic matter and microorganisms in the fluid, enhances the mass transfer effect and improves the biochemical reaction rate of the reactor, thereby greatly improving the efficiency of the reactor treatment. EGSB reactor is always in cylindrical column shape with a high height/diameter ratio, generally up to 3~5,can be up to 15 to 20 meters high. EGSB has high loading ability, the organic loading rate(OLR) is 2~3 times higher than UASB, up to 6 ~ 18mgCOD / m³.d.

- IC Reactor (Internal Circulation). IC is an internal loop type of anaerobic reactor, similar to the series of two UASB tanks, and like EGSB, with a big height/diameter ratio. The biggest difference in operation between IC and UASB is the performance of bearing shock load, IC can automatically dilute the input materials through the internal circulation, effectively ensuring the stability of input fluid concentration in the first reaction chamber. The second advantage is that it only requires a short residence time, suitable for considerable biodegradable sewage with high SS content. IC has a significant advantage over UASB,due to the high flow rate of IC, SS does not accumulate in the reactor, and sludge can maintain high activity.

The material for the above reactors can be enamel steel tank, made of titanium-alloy enamel steel plate, with double-sided enamel coating, beautiful appearance, easy to clean, easy maintenance with good wear resistance, corrosion resistance, impact resistance,insulation performance, anti-static; No special anti-corrosion treatment required, lifetime designed for 30 years at least.

In addition, the above reactors can be also LIPP tanks under unique construction method. During construction, the steel coils with a certain width are taken into the molding machine by uncoiler, to be processed into the required geometry, and then to be bended and seamed through bending machine, to form a round of spiral protruded ridge with 30mm-40mm width at outer side of tank, playing the role of strengthening the tank.

3.Biogas Storage Process

For tank type of digester, structure of integrated all-in-one with biomass fermentation and biogas storage combined together is always welcome by customers, in order to reduce investment. The biogas storage is in the form of double-membrane gas holder mounted on top of tank. It consists of inner/outer membrane,support,air blower,anchoring device and other auxiliaries.It can also be free-standing type on the ground when tank is very high, to avoid affection of speedy wind for safety. Top of tank has to be covered by steel plates too, what’s more, additional civil works for gas holder is caused. In this regard, it will increase the investment significantly.

Another simple design is gas bag that made of reinforced single PVC membrane, anchored in specif area on the ground.

No special biogas storage devices required when digester is HDPE enclosed anaerobic lagoon or floating soft digester that made of PVC membrane;

4.Biogas Cleaning

Biogas pre-treatment process is mainly to remove hydrogen sulfide, moisture and solid impurities in the raw biogas, reduce corrosion and wear for subsequent equipment. Biogas pressure to be increased for transportation and regulated to meet the requirements of inlet pressure of follow-up equipment, involving equipment such as roots blower with explosion-proof motor under anti-corrosion treatment.Moisture and solid impurities can be removed through physical means while the most difficult is the removal of hydrogen sulfide. Traditional methods are chemical dry type(iron oxide) and chemical wet type(sodium carbonate) or a combination of both, or the latest biological desulphurization technology(oxygen-absorbing microbial absorption solution).

Our patented ALBS series integrated biogas pre-treatment system, provides all-in-one solution to perform the above functions,it mainly includes the following:

- Desulphurization tanks;

- Water&particles removal tanks;

- Roots blowers, 2 units(one for operation,the other for standby);

- Constant-pressure feed system(Variable frequency drive,LCD display etc);

- Instruments,like pressure gauge,flow meter etc;

- Base steel frameworks.

A on-line biogas analyzer is strongly advised, to measure the main components (methane,hydrogen sulfide,carbon dioxide,oxygen etc) in the purified biogas.

5.Biogas Utilization

5.1 Bio-natural Gas.If biogas is used to produce CNG(Compressed Natural Gas) for vehicle or gas grid networks, except the above biogas pre-treatment, decarburization process is required for further treatment. Now we could provide containerized type biogas upgrading system in conjunction with the four kinds of mature technologies, including MS(Membrane Separating), PSA(Pressure Swing Absorption), MEA/MEDA(Mono Etobaccool Amine/ Methyldiethanolamine) and DWW(Pressurized Water Washing).

The subsequent compressor is to be installed for increasing pressure to a certain degree(e.g. 20Mpa), to be fed into tank lorry through gas dispenser.

5.2 Combined Heat and Power(CHP).

Purified biogas is combusted in the internal combustion engine of Combined Heat&Power Plant(CHP); Electricity for which compensation can be obtained is generated, for local use or connected with power grid networks. The heat from engine jacket water and exhaust can be used for digester heating, or return to respective company for warming,bathing etc. The CHP can be regulated in terms of its utilization. Consequently,it can correspond to various remuneration regulations and be complemented through other heating concepts.

We could provide quality CHP with high electrical efficiency,low oil consumption and long overhaul time.Our ACG and ADG series CHPs are associated with world-famous engine technologies, such as USA Cummins and German Deutz. Single unit capacity from 20kW to 400kW, to be configured automatic air-fuel ratio system, automatic oil feed system, exhaust purification mechanism and Grid connection cabinet,etc. according to customers’ actual requirements.

5.3 Biogas Boiler.

Purified biogas can be used for producing hot-water or steam through boiler,which is equipped with high efficient burner. Hot water and steam generated are always used for material drying.This kind of utilization is very popular with food-processing factories,feed mill plants etc. Biogas production is not depending on climatic factors,and it can be stored and converted into energy at any time,it can meet base-load and peak-load requirements.

Each country and region for the pressure vessel has a corresponding quality and safety standards,Special attention should be paid to boiler design and quality control,make it be subject to the quality standard as local relevant authority requires.

6.Digestate Treatment

Digestate means residue and slurry after fermentation,be rich in N.P.K, humic acid, organic matter and trace elements.Therefore the solid substance of digestate can be used as soil additive or compost,and the resultant liquid nutrient concentrate replaces the mineral fertilizers.And the separated water is processed so that it can be directly routed in the surrounding water body or can be used as processing water.Fermentation residue from bottom of digester is generally with water content 15~20%, after sediment treatment,through a dedicated solid-liquid separation equipment, after dried under sunshine and bag packed,the precipitations can be made for solid organic fertilizer. This is a relatively primitive approach, suitable for customers with little budget on small biogas plant.

For the project with big digestate output, considering the return on investment, the solid organic fertilizer can be processed into granular fertilizer. The general process includes solid-liquid separation, batching system, mixing system, granulation, hot air oven drying and cooling , Dust removal, screening systems and packing machine.

The slurry flows out of digester at upper position,together with the filtration liquid from residue,it can be used for nearby plant irrigation or horticultural purpose after further processing.If waste material is solid like livestock manure etc,slurry could be partially returned to pre-mixer with raw waste,in order to reduce water consumption,but have to keep carbon/nitrogen balance of feestock,which is best at 25 : 1.

7.Further Treatment of Slurry

In order to prevent pollution on the environment, in the countries and regions with strict laws of environmental protection,the fermented slurry still has to be cleaned further. ALONG could offer solutions to solve this problem by air flotation, A/O(Anaerobic-Oxic) or A2/O(Anaerobic-Anoxic-Oxic) technologies. Their common function is to remove organic matters in slurry.After treatment,the purified water can be discharged environmental friendly.What’s more,we can provide membrane separating technologies for treating slurry further.The water after purified can be used for process water for local usage in customers’ plant,such as food-processing industry.

The whole biogas project and sewage treatment process design principles:

1. Advanced technology, reliability, and adaptability.

1.1 According to the actual situation of the plant, choose the most advanced technology program.

1.2 According to the actual situation of the local, choose a successful case of the project to ensure that the project can be long-term stable operation.

1.3 According to the owners of economic conditions and operational skills level, select the most appropriate program, easy to actual operation and maintenance.

2. The principle of maximizing economic efficiency

2.1 to ensure the advanced nature of technology on the basis of optimizing the process and the various unit design, reduce one-time investment to ensure the best cost-effective and the shortest payback period.

2.2 follow the concept of circular economy, the entire field of energy flow analysis and design, to minimize energy consumption, to ensure that biogas projects for enterprises to bring the overall maximum benefits.

3. The principle of maximizing environmental and social benefits

3.1 to the product (biogas, biogas residue, biogas slurry) to make full use of, and focus on design and landscaping, so that the overall area of the station area and the harmonization of the community.

3.2 The design and implementation of the process to comply with national and local laws and regulations and industrial policies to ensure that the project in line with local environmental, economic and social development planning, after the completion of the project can improve public heating, catering and other energy, and play an exemplary role in driving the local economy And social development.

Livestock Manure

Hunan Along New Energy Technologies Co., Ltd.provides a complete set of process design and relevant equipment supply from fresh livestock manure to biogas energy based on principles of rational and reliable technology application, maximum economic efficiency, maximum environmental and social benefits.

Description of technological process

1.Pre-treatment of feedstock

Pre-treatment process is mainly to adjust the feedstock concentration and remove large inorganic suspended solids. Pigs, cattle and sheep manure contain a small amount of fiber and inorganic solid matter, and chicken manure contains gravel and feathers, etc., which must be removed in the pre-treatment process to reduce the loading of follow-up processing and avoid wear for the relevant equipment.There is always a existing fecal collection basin in livestock farm. The mixture of manure and washing water is pumped into grille canal. Mechanical grilles would be installed in front of canal, to be used for removing large size of suspended solids and a variety of debris(Alternative solution is to use a spiral extrusion separator,to remove more solids in the waste water, while the separated solids can be used for bio-fertilizer making if it’s the main purpose).

The waste water gets out of grille canal and is pumped into hydrolysis regulation basin, where a vertical mixer is installed for TS(Total Solids) content regulated to be 6~12%. With mechanical stirring, VSS could be totally resolved in the water. A certain degree of hydrolysis would occur in this basin. The sediment like sand at the V-shaped bottom of basin needs to be taken out regularly by spiral desander.

Necessary measurements of temperature, pH, C/N elements of waste water in the basin should be done preliminarily. If possible,a certain amount of straw could be added,because livestock manure is rich in nitrogen element while straw is poor,so their mixtures can reach the most proper C/N balance which prefers around 25 : 1.

What’s more,make sure that no harmful substance exists in the waste water which may affect the normal metabolism of anaerobic bacteria.

In case of pre-heating of feedstock, the hydrolysis regulation basin would be designed as reinforced concreted structure underground with cover. Inclined agitator to be installed for stirring. Extruded plastic sheet to be installed inside for heat keeping. Spiral plate heat exchanger to be installed inside the feed pipeline.Hot water could be from biogas boiler.

Cutting & grinding pump if installed in front of charging pumps before digester, to be used for cutting the remaining long soft feather, fibers, impurities and the like, to avoid clogging and wear for the subsequent equipment.

2.Process of Anaerobic Digestion(AD)

As the mixture of livestock manure and washing water is a kind of organic waste water with high TS content at 6~12%, therefore CSTR(Continuous Stirring Tank Reactor) type of digester is strongly recommended.The mixture to be fed into digester through bottom entrance. Digester is equipped with stirring system, enables mixture to be in full contact with micro-organisms,to speed up the process of hydrolysis,acidification,acetic acid formation and methane formation. The biogas slurry is automatically discharged and the residue is periodically pumped out of digester. Biogas generated is collected in the gas holder on the top of the reactor or flows into the free-standing gas bag on the ground. HRT(Hydraulic Retention Time) varies from 15 to 30 days depending on the actual TS% and reactor temperature.

If project budget is sufficient, we would advise customer to adopt two-stages anaerobic fermentation process which is CSTR + UASB, to improve waste utilization and increase biogas production,meanwhile waste water could be cleaned further, total COD removal rate could reach 95%.

The waste water from CSTR enters UASB digester through the water distributor at the bottom of the reactor. At the bottom of the reactor there is a high concentration, highly active sludge blanket, where most of the organic matter is dissolved and fermented to methane and carbon dioxide. Due to the stirring of water flows and bubbles that full of biogas, there is a floating sludge layer above the sludge blanket. Gas,Liquid and sludge particle Solids are separated automatically through a special three-phases mechanical separator. Biogas flows into the gas storage chamber, sludge particles automatically fall to the sludge blanket, slurry gets out of reactor at clarification chamber.

In case of TS% at 3~5% of waste water from CSTR with high content of suspended solids, USR(Up-flow Solids Reactor) type of digester is also good. Waste is pumped into digester from bottom of reactor, and contact with activated sludge during up-flowing, so that the biomass to be quickly fermented. Unprocessed biomass solid particles and microorganisms remains inside reactor by natural sedimentation, and the bio-liquid overflows from the upper part of the digester.

If project budget is tight and customer can’t afford high investment by adopting process of CSTR enamel steel tank, we will advise client to use our HDPE membrane enclosed anaerobic lagoon as digester. This kind of digester is a regular trapezoidal lagoon; Lagoon surface and bottom are rectangular (Surface is large, bottom is small); The trapezoidal slope is designed at generally 30 degrees to 45 Degrees according to actual volume of lagoon.It is a complete enclosure sealed by HDPE geo-membrane.

3.Utilization of Digestate

Digestate means residue and slurry after fermentation, be rich in N.P.K, humic acid, organic matter and trace elements. Therefore the solid substance of digestate can be used as soil additive or compost, and the resultant liquid nutrient concentrate replaces the mineral fertilizers. And the separated water is processed so that it can be directly routed in the surrounding water body or can be used as processing water.The fermented liquid could also be partially returned to fecal collection basin, with the purpose of saving feed water sources.

4.Utilization of Biogas

Generally speaking, the utilization of biogas could be following purposes as below:For cooking. For small project with daily biogas production less than 100 cubic meters, biogas after cleaned could be used for cooking in the farm, or distributed to nearby households through pipeline.

For combined heat and power. The biogas can be used for power generation. Generator with heat recovery system could provide hot water for digester heating or farm workers’ bathing,warming,etc.

For bio-natural gas. For big project with sufficient biogas production, the biogas can be used for making bio-natural gas through our desulphurization and decarburization system. Through pressure devices and feed system,bio-natural gas could be fed to vehicle or into national gas network.

For boiler or lamps. Biogas after cleaned could be fed for boiler for warming in the farm or biogas lamps for lighting of farm or animal breeding e.g. The hatch of poultry.

Industrial Organic Sewage

The process water, discharged by food industry, feed mill,paper mill,etc., containing high content of COD and BOD5, featured with good biodegradability, is a great resource for biogas production.The purpose of sewage treatment determines the choice of specific process. General speaking, there are three kinds of situations:

1.Purifying sewage is the only purpose, to remove organic matter as more as possible, to make water discharging environmental friendly. In this case, we adopt separation, air flotation, A2/O (Anaerobic-Anoxic-Oxic) technologies, etc.

2.Only for the purpose of biogas production. The loss of organic matter should be minimized in the front end of filtration. Improvement of BOD5/CODt ratio is necessary to raise the loading capacity of reactor. Biological technology is anaerobic digestion.

3.Combination of biogas and purification.

Herewith we only explain the technological process for biogas production.

1.Primary treatment

Removal of big-size suspended solids and harmful substance, regulation of pH value and temperature, improvement of biodegradability and C/N element ratio would be implemented in this step.Mechanical grilles, Spiral centrifugal and extrusion press are suitable for filtration. If composition is okay, the separated solids could be fed to animal, but exclusive of sands and the like. So we always advise clients not to mix the process water with the washing water in the works.

For the waste water with high content of insoluble COD(eg.lignin) when its BOD5/CODt ratio is lower than 0.5, it’s better for hydrolysis to mainly occurs in this step, to decompose insoluble COD into soluble COD, to degrade macromolecules into micromolecules.

2.Anaerobic digestion

The proper anaerobic reactor is UASB(Up-flow Anaerobic Sludge Blanket) when total solids content lower than 5%. Waste water enters reactor through bottom-located distribution system. There is a sludge blanket at the bottom position, most of organic substances are fermented here when biogas is formed. Resulting from stirring of flow and gas bubble,a sludge suspension layer is formed above blanket.A three-phase separator is fixed at upper position in reactor. Via it,the separation of gas,fermented liquid and solids attached on gas bubbles would be achieved. Gas is stored in gas holder on top or pressed out through gas pipe, liquid flows out of reactor and sludge solids slide down into sludge blanket.

The loading capacity of UASB reactor could reach 3 ~ 12mgCOD/m³.d, HRT(Hydraulic Retention Time) is 5~10 days, suitable for biological treatment of high concentration organic waste water. COD removal could reach 85 ~ 90%.

EGSB (Expanded Granular Sludge Blanket) is the third generation of anaerobic reactors developed on the basis of UASB. Unlike the UASB, EGSB has a dedicated sewage recovery unit. The expansion of granular sludge blanket improves the contact between organic matter and microorganisms.

IC (Internal Circulation) has good performance of anti-load shocking. It has a large height-diameter ratio,seemingly two UASB in series. The incoming waste water could be diluted automatically through internal circulation. In this regard,the stability of concentration of waste water in the first reaction chamber is guaranteed. Due to high up-flow speed,suspended solids do not accumulate in reactor and sludge can maintain high activity.

Food Waste

Food waste is a kind of available resources of biomass energy.Kitchen waste, collected from restaurant, school, government offices, works’ canteen, hospitals, etc., and fruit&vegetable waste can be mixed together. Big solids eg. bones,chopsticks in mixture are removed through mechanical sorting system; Then by press machine, the separated oil can be recycled as industrial grease eg. bio-diesel, while the sorting of metal occurs before crushing of separated solids, which then are conveyed to be mixed with liquid out of mixture of oil&water, to be fermented in anaerobic reactor for biogas production.

General Flow-chart of biogas plant based on food waste:

1.Sorting of food waste

In addition to a large amount of organic matter, there is also small amount of components in the food waste that can not be biodegradable, such as bones,plastic,glass,stone,metals,shells,wood and silk,etc., should be sorted out to ensure the performances of the follow-up process.2.Press treatment

Separation of solids and liquid is implemented by press system; The liquid is a mixture of water and oil, the segregation of them is done by centrifugal; The separated oil can be utilized for bio-diesel production, while the separated water would be mixed with solids in the following process.

3.Separation of metal

The water content is 40~50% in the waste after press. The metal in the waste must be removed by technical means,eg. magnetic separation, to avoid physical damage to the subsequent equipment. This also plays the role of resource recovery.4.Crushing and primary treatment

The waste would be crushed to be in fine dimensions, then to be mixed with separated water from above #2 step, to be processed in pulp condition. The water content of mixture is regulated to be in the range of 10±2%.5.Anaerobic Digestion

Feedstock is pumped into reactor by progressive cavity pumps. The proper reactor is CSTR(Continuous Stirring Tank Reactor), equipped with agitator and temp. monitoring. It can be all-in-one solution, a combination of biogas production and storage, with gas holder mounted on top of reactor when its single volume is not big.Landfill Gas

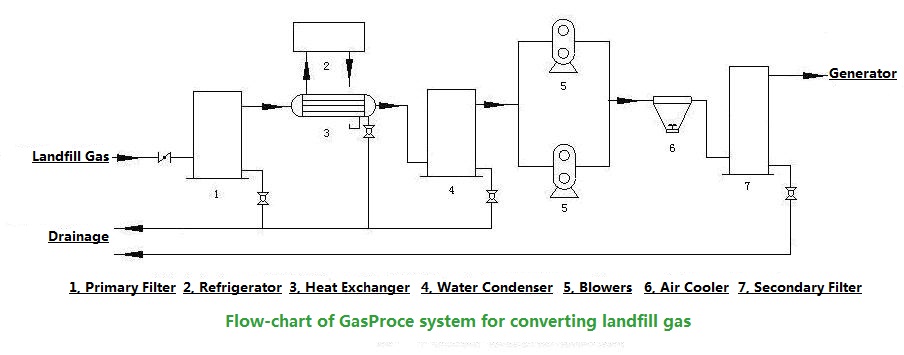

Landfill is the site for stacking of municipal refuse. A big landfill under proper design could produce a considerable amount of biogas, as a great green energy for power generation.A sanitary landfill is always equipped with perforated tubes, which are connected to suction and purging system, to delivery gas to the site for conversion.

Landfill gas contains methane(40~70%), carbon dioxide(30~60%), hydrogen sulfide, saturated water vapor, high hydrocarbons(C2H6 - C7H16), oxide of ammonia/nitrogen/oxygen/sulfur/alkanes /acids/benzene/silicon, salts and even physical particles. And its flow, pressure, temperature and concentration are unstable, direct combustion in engine would cause corrosion and grinding for generator and other relevant equipment, as well as pollution for atmosphere. So it must be cleaned before the use;

Our GasPro system is designed to preform this role of converting landfill gas, with functions of dehydration, dehumidification, edulcoration, boosting, pressure-stabilization, thermoregulation, automatic/remote controlling and on-line detecting,etc.

● Filtration; Physical particles could be observably removed;

● Filtration; Physical particles could be observably removed;● Multi-stage dehydration could reduce the temperature of gas dew point,as well as the water vapor content;

● Freezing function for condensation and precipitation of harmful gases;

● Adjusting gas temperature in proper condition to feed engine;

● On-line detecting system for measuring gas composition timely(optional);

● Advanced control system could stabilize the gas outlet pressure and temperature;

● The gas flow is automatically tracked rooted on the requirements of engine;

● Equipped with alarms and protections for over-pressure and over-temperature, to ensure safe and reliable operation of system in the long-term;

● This matched system could make engine runs under condition of fixed thermal value, to improve the stability of engine operation and protect the gas collector.

GasPro system uses programmable controller - PLC control, with functions of data acquisition, on-line detection and alarm. Standard communication interface to be provided in synchronization with the owner’s control system per clients’ requirements, to achieve the purpose of unattended and fully automatic operation:

1.A programmable PLC controller for data acquisition and processing;

2.With function of remote data transmission;

3.Through standard industrial Ethernet to read data when system in operation;

4.Site controlling mode at local engineering station by the use of LCD touch screen. Through data transmission to achieve the purpose of remote controlling, eg. start/stop signal;

5.The use of professional computer for processing of data and signal. Configuration software and past records are stored in the hard risk of computer;

6.Within authorized scope, engineer could modify the parameter settings of alarm and shutdown.

Flow-chart of GasPro system for converting landfill gas:

Landfill gas is mainly used for power generation in actual projects. They are always big scales, big generators or CHPs installed with synchronization with national grid. So stability of feed gas at pressure, temperature and cleanliness is very important to guarantee the life time of the valuable generators, to get reliable ROI(Return on Investment).

Biomass Stalks

Crop Straw is a generic term for the stems and leaves of a mature crop, usually referred to as the remainder of wheat, corn, potato, rape, peanut, soybean and other crops (usually coarse grains) after harvesting the seed. Energy grass are the perennial tall herbs or semi-shrubs, such as Pennisetum, giant grass, Arundo donax, switchgrass, mango crops,etc.

Energy grass are the perennial tall herbs or semi-shrubs, such as Pennisetum, giant grass, Arundo donax, switchgrass, mango crops,etc.Crop straw and energy grass are rich in organic matter, whose majority is composed of lignin, cellulose and hemicellulose that can not be easily decomposed. Special technology and long time required in the hydrolysis process, so it is recommended to choose raw biomass that are soft and fresh with low lignin and high sugar contents.

As these biomass has low ammonia and phosphorus content, not good for microbial metabolic activity, increasing the difficulty of biological decomposition. In practice, it is recommended to mix with human or animal manure to improve biogas production if wet type fermentation is adopted.

Due to high solids content in some special biomass, it is also suitable for dry type fermentation, or a combination of dry type hydrolysis process and wet type methane formation.